ULTRA WIDE ANGLE COMPACT COLOR CCD CAMERA

CC1601A

Discontinued

FEATURE

Ultra-wide 160° Viewing Angle reduces blind spots when camera is mounted in a low position.

Compact and lightweight design for easy installation.

Electronic iris for various lighting situations.

Ultra-wide 160° Viewing Angle reduces blind spots when camera is mounted in a low position.

Compact and lightweight design for easy installation.

Electronic iris for various lighting situations.

Application Examples

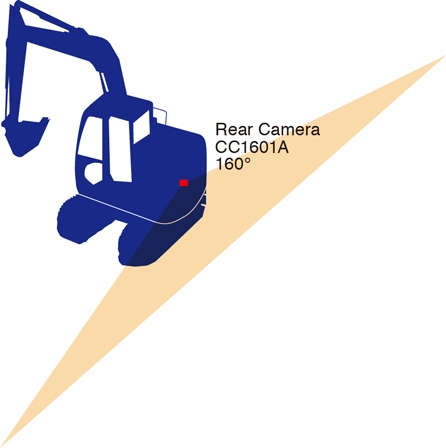

【For Hydraulic Shovel】

【For Hydraulic Shovel】

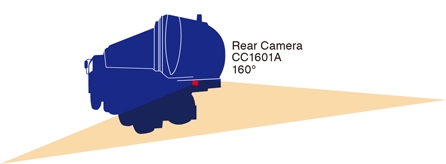

【For Garbage Truck】

Ultra-wide Angle Of View

Built-to Meet The Most Rigorous Commercial Standards

Clarion’s reliability is backed up by one of the world’s most rigorous production line quality assurance systems. We know that our in-vehicle equipment must perform consistently and reliably no matter what the application. Whether it’s a garbage truck,bus, truck, forklift, agricultural, construction, or maritime machinery we build it to exceed your requirements.

Built-to Meet The Most Rigorous Commercial Standards

Built-to Meet The Most Rigorous Commercial Standards

Operating Temperature Testing

To assure reliable performance in a wide range of environments, testing is conducted at a temperature range of –30ºC to +70ºC.

To assure reliable performance in a wide range of environments, testing is conducted at a temperature range of –30ºC to +70ºC.

Thermal Shock Resistance

Cycled from -40C to +85C, Clarion cameras are put through the gauntlet. This test is intended to expose any problems with solder joints, the PC board and the aluminum housing.

Cycled from -40C to +85C, Clarion cameras are put through the gauntlet. This test is intended to expose any problems with solder joints, the PC board and the aluminum housing.

Water Resistance Using

We check for water penetration inside the camera to ensure watertight integrity.

We check for water penetration inside the camera to ensure watertight integrity.

Vibration Resistance

Built to last! Designed to withstand up to a 6.8G (G-Force) shock.

Built to last! Designed to withstand up to a 6.8G (G-Force) shock.

Impact Resistance

Testing is conducted to confirm that the appearance and function are not affected after an impact such as being dropped.

Testing is conducted to confirm that the appearance and function are not affected after an impact such as being dropped.

Designed and tested to withstand transient voltages and radiated emissions present in today's commercial applications.

・Overvoltage / Undervoltage.

・Low Frequency Surge / High Frequency Surge.

・Power fluctuation such as engine cranking or temporary blackout.

・Radiated emissions.

・Electrostatic discharge.

・Overvoltage / Undervoltage.

・Low Frequency Surge / High Frequency Surge.

・Power fluctuation such as engine cranking or temporary blackout.

・Radiated emissions.

・Electrostatic discharge.